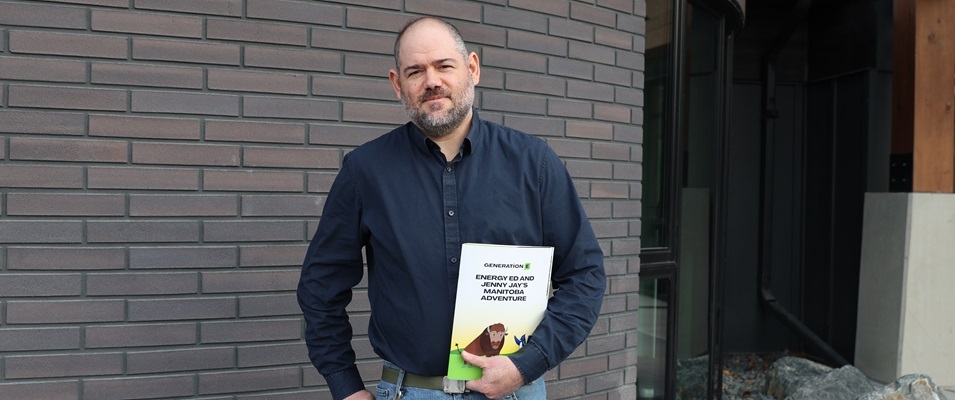

It’s been just 18 months since Chris and Maria Holbrow first opened a bakery in their Niverville home’s commercial kitchen, and now their new expanded digs at 69 Main Street are finally heating up.

Within the confines of the old post office, the Holbrows have been hard at work gutting the interior, plumbing and rewiring, and assembling commercial bakery equipment that’s been shipped in from around the world.

This is the new home of Forgotten Flavours, a homespun company whose products include organic artisan breads, pastries, cereals, and pastas.

Maria was originally the sole operator of this small business, but her husband Chris has now quit his corporate job thanks to the bakery’s instant success.

Chris says that one of the biggest renovations needed in their new building was the installation of heavy-duty three-phase electrical power.

“It’s been an expensive and time-consuming endeavour,” says Chris. “But it’s the lifeblood to all of our equipment.”

The bread oven alone is a marvel to witness. Built in Italy and retailing for $150,000, it stands floor to ceiling and contains four deep baking chambers that are fed by a conveyor belt running vertically from chamber to chamber.

Arriving disassembled on pallets, the Holbrows had to fly in a special assembly technician from Spain to put it together. By early February, the couple were hard at work familiarizing themselves with the oven’s many bells and whistles.

“We understand science from how Maria’s wild yeast works,” Chris says. “Now we’re learning science on how every aspect of an oven will change your bread.”

Without question, the oven will change their productivity. Where the couple was able to produce 70 loaves in a production day before, this Italian oven will pump out 80 loaves of bread per hour.

“So what we normally do in eight hours, we can do in one hour,” says Chris. “Our production will increase tenfold, easily.”

But the oven is only one piece of the impressive automation going on in the new Forgotten Flavours kitchen.

Next to the oven stands a proofing room which provides the perfect temperature for 100 loaves of bread to rise. Nearby, two 130-quart commercial dough mixers come equipped with automated technology that adds water to the dry dough ingredients in the perfect quantity and at the optimal temperature.

Where cutting, weighing, and dough rolling previously required a lot of manual labour for the couple’s signature brioche buns, an automated bun roller now turns every bun into the perfect size and shape.

Along one wall stands a long series of coolers where the proofed bread goes to spend 18 hours in a fermentation process before it’s baked. It may be one of the most unique characteristics of Maria’s bread baking, a process that sets it apart from most commercially produced breads.

“That’s why our bread has such a low impact on people’s guts,” says Chris. “It is fermenting for so long that it eats up all those carbs and gluten proteins. Good for people like myself with chronic digestive issues.”

In the early stages of the new bakery’s operation, the Holbrows hope to hire two full-time production employees. In a few more months, when the business expands to include a café and storefront, more staff will be needed.

“We’re really excited for the future and how many jobs we’re going to provide for Niverville,” Chris says. “But also we’re just excited for the unique [products] we’re going to be able to bring to Niverville.”

The Holbrows aren’t just entrepreneurs. They’re also parents to three growing kids, children who they believe deserve the most wholesome food options available.

The organically grown Einkorn, whole wheat, and rye grains that make up Forgotten Flavours wild yeast products are sourced out of Treherne, Manitoba, and are milled into flour in the couple’s commercial kitchen.

“Our kids already understand the importance of what we put in our mouths,” says Chris. “We probably get a little preachy about it, but our kids are our future and they need to understand where our food comes from and what real ingredients are.”

These same freshly milled flours will also be available in the retail section of the storefront.

As well, the couple intend to keep the home commercial kitchen active as a small-scale test kitchen and a place where they can continue to host bread-baking workshops.

“It’s not just about buying bread from us,” Chris says. “We want to be able to get a lot of people making it in their own homes.”

Now on the cusp of large-scale production in their new space, the Holbrows look back over the past months and feel a deep sense of gratitude to the many people who helped them get here.

These include their landlord, who helped pave the way to make the building workable, to the staff at Wm. Dyck & Sons, who went above and beyond to locate the hard-to-find supplies and forklift their equipment into place.

They’re grateful, too, for residents like John Funk, who pulled together a crew of men on short notice to move the Holbrow’s two 1,700-pound mixers into position.

“So many stops have been pulled out to help us,” says Chris. “It’s been humbling beyond words. We would not want to put our business anywhere but here. This is community.”