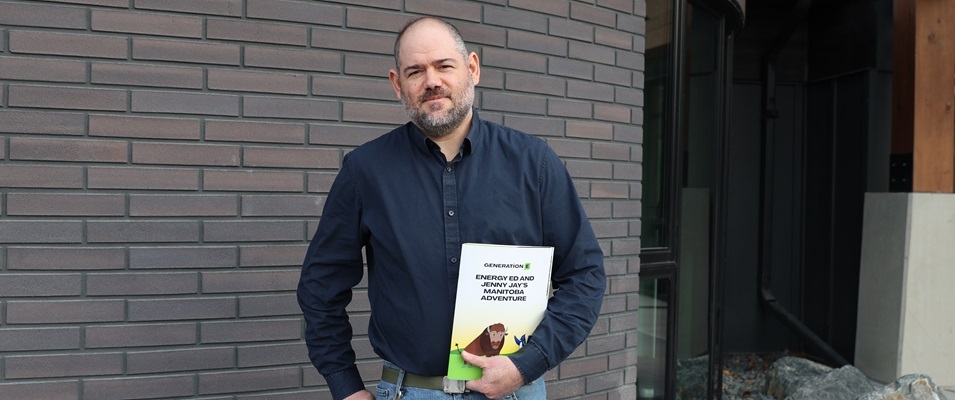

Merrick Sandulak has been a volunteer firefighter in Niverville for three years and has lived in town since 2000. After graduating from high school, he worked as a welder for three years.

Sandulak had his first encounter with firefighters when he landed in the burn unit at Health Sciences Centre, having survived a freak industrial accident with severe burns to his upper body and face. There, he met firefighters who had been injured in a fire that had claimed the lives of two deputy chiefs. Sandulak was so impressed by the camaraderie of the firefighters and how they spoke of the guys back at their fire hall.

“It really piqued my interest,” Sandulak says, who gradually worked himself back to full-time work by the age of 22.

In 2013, he became a volunteer firefighter in Niverville, earning his HAZMAT (hazardous material) certification and Level I within a year. Next, he hopes to achieve Emergency Medical Responder and Firefighter Level II. He has his Class 4 driver’s license and has already written the test for air brake certification.

Sandulak currently works full-time as an estimator for Fusion Industries. He is married to Larissa and has two boys and a girl between the ages of two and six.

His first firefighting experience came when he responded to a big barn on fire not far from Niverville. The full contingent of volunteer firefighters was present.

“I recall thinking how chaotic it would be, but I was impressed how our leaders delegated jobs,” he says. “We each focused on the job we were given, and with that teamwork everything went smoothly. We are taught so much by the eight members who work full-time for the City of Winnipeg. They share their knowledge and experience with newbies in a very respectful and generous way.”

Sandulak acknowledged that firefighting isn’t always glamorous, specifically when it comes to remaining onsite after a call. “Very often one truck and crew remain on the site watching for flare-ups and following a backhoe or tractor that is removing and exposing hot spots. The rest of us return to the hall where hoses are laid out and washed along with trucks, masks, and turnout gear. Inner and outer shells have to be washed separately in 45-minute cycles in our commercial washer, and then dried on a special dryer rack. Air tanks get refilled.”

The order and cleanliness of the fire hall is impressive, thanks to special racks for all the turnout gear. When asked about this, Sandulak grins with pride. “I had something to do with that,” he says. “My welding skills came in real handy. It’s a great feeling to give back to the community.”